For detection of dangerous gases and vapors in environment of production, boiler rooms, gas plants, paint shops, freezers, warehouses, underground garages and other comerical spaces. With help of four-level control unit evaluates current from up to 8 concentration sensors. Control unit converts the signal to relay outputs to 10%, 20%, 30%, 40% and 50% of the sensor range.

Example:

Concentration is 10%

I. relay will open and start first level of ventilation.

Concentration is 20%

II. relay will open and start second level of ventilation.

Concentration is 40%

III. relay will open and lights up the warning signs.

Concentration is 50%

IV. relay will open and start warning sirens.

With connector RS485 it is possible to connnect up to 9 ASIN ACU`s control units with ASIN M monitoring. In one moment you can monitor up to 72 sensors. Thanks to RS485 you can integrate ASIN M into master control system.

Amonia, NH3

Ethylene,C2H4

Freons, R134 A, R1234yf

Chlorine, Cl2

Oxygene, O2

Methane, CH4 – CNG, earth gas

Propane, C3H8 – LPG

Hydrogen sulfide, H2S

Hydrogen, H2

Aceton

Acetylene

Butanol

Diethyl ether

Ethanol

Ethyl acetate

Ethylene

Methanol

N-heptane

Pentane

Propanol

Toluene

Xylene

Nitric oxide, NO

Carbon monoxide, CO

Carbon dioxide, CO2

Sensors are intendet for use in normal environment. Easy installation and maintenance.

Calibration by replacement

Protection: IP20

Operating temperature: 0 to +40°C

Relative humidity: 0–90% rh

Sensors are intendet for use in normal environment with higher protection needs.

Sensors can be equipped with heating for applications in low temperatures.

Protection: IP62

Operating temperature: 0 to +40°C, with heating to -40°C

Relative humidity: 0–90% rh

Sensors are intedet for use in environment with explosin hazard.

Case of the sensor is robust from high grade aluminium. Certification Ex II 2G Ex d IIB T6 Gb.

Protection: IP60

Operating temperature: 0 to +40°C

Relative humidity: 0–90% rh

Are equipped with electrochemical, catalytic or infrared sensors. Current loop (4-20mA) signal is directly proportional to measured concentration. Equipped with pump for measured gas. ASIN ACU functions can be added. Measure one or two components of the gas.

Protection: IP20

Operating temperature: 0 to +40°C

Relative humidity: 0–90% rh

Electrochemical sensing devices basically consist of electrodes surrounded by an electrolyte solution enclosed behind a gas permeable, hydrophobic membrane. Gas molecules diffuse across the membrane to enter the electrode/ electrolyte interface where chemical and electrochemical reactions occur to generate measurable electrical current flow. Main advantages are high sensitivity, excellent selectivity and linear response. Disadvantage is relative short lifespan, average is 2 years.

Infrared detectors are based on the principle of infrared absorption by gas molecules at specific wavelengths in the infrared region. The ASEKO sensor utilizes linear NDIR. The active detector is covered by an optical filter that allows transmission of infrared radiation at a specified wavelength where the target gas is known to absorb.

These sensors respond to all combustible materials and are applicable only for measurements in air or gases with sufficient oxygen concentration. Catalytic bead combustible gas sensors basically consist of hot filaments (active and reference elements) enclosed behind a sintered stainless steel flame arrestor. The active element is treated with a catalyst to effectively burn or oxidize the gas while the reference element is nonreactive and provides compensation for ambient conditions; temperature and humidity.

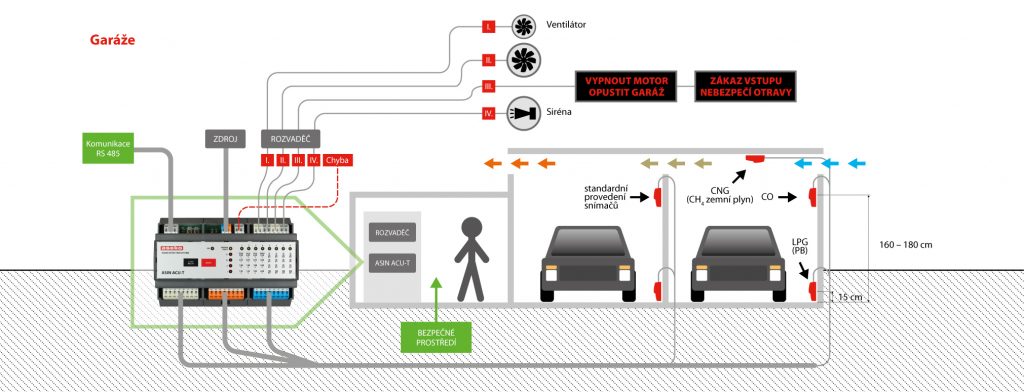

For detection of carbon monoxide in underground garages we offer four-level detection based on requirements of EU. Also sensors for LPG, CNG, nitrogen oxides. Warning signs and sirens.

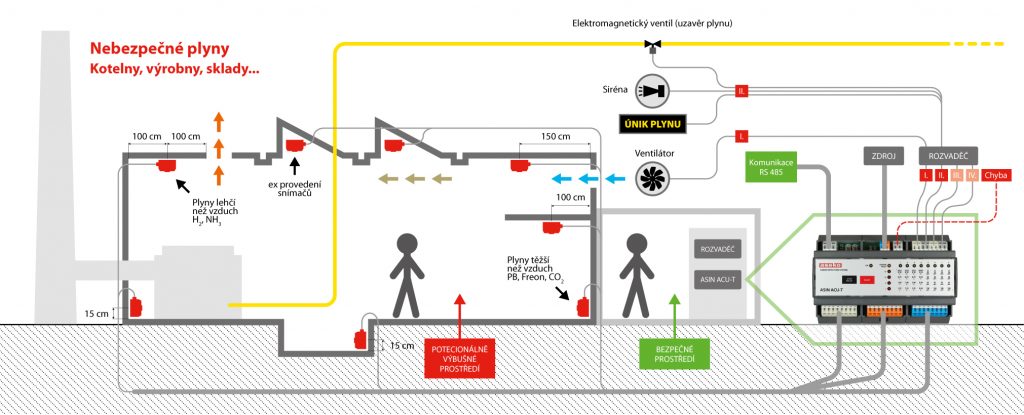

ADS detection system provides full coverage of boiler room. Detection of heating gas (earth gas or propane) also detection of hygienically dangerous concentration of carbon monoxide and detection of criticaly high temperature and boiler room flooding. For complete system we provide sirens and warning signs.

For calibration and warranty or post-warranty service of ASEKO devices, please use our service system.